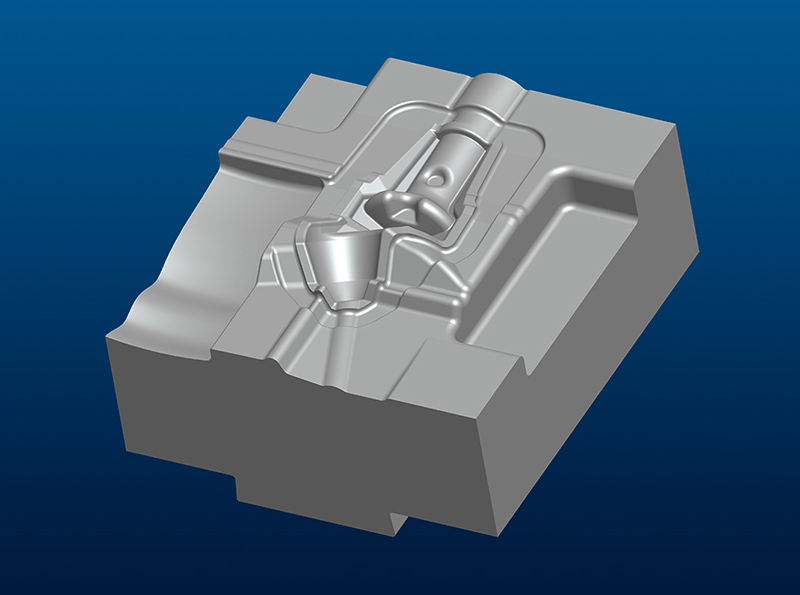

Unit Forgings utilizes the latest state-of-the-art technologies when producing our products. Forged part geometry and die design are fully computerized using Creo Elements/Pro which enables us to design forgings and the related tooling quickly and accurately.

We are able to use CAD data from our customers’ exported files such as STEP, STL, or IGES. The use of CAD files is encouraged even in the quoting process as it is much faster and reduces the chance of error. In return, we can provide CAD files of the forging design back to our customer early in the design process.

We also use our CAD tooling data to drive our 3 axis CNC milling machines, providing tooling geometry that is accurate and consistent every time the tooling is worked on.

We also use a finite element analysis program, DEFORM, to help us design dies and the forging process. Deform allows us to simulate the flow of the material in the dies, which helps us avoid designs that are prone to problems in the manufacturing process. It is our efficiency and attention to detail that enables us to provide our customers with much longer die life, better production rates and reduced die maintenance costs.